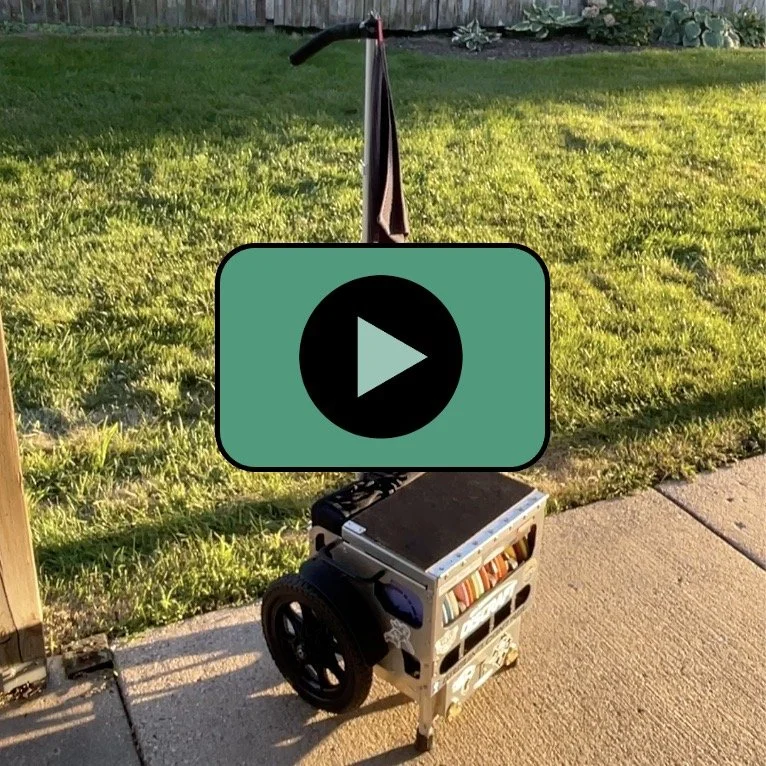

Disc Golf Cart

Sep 2019

-

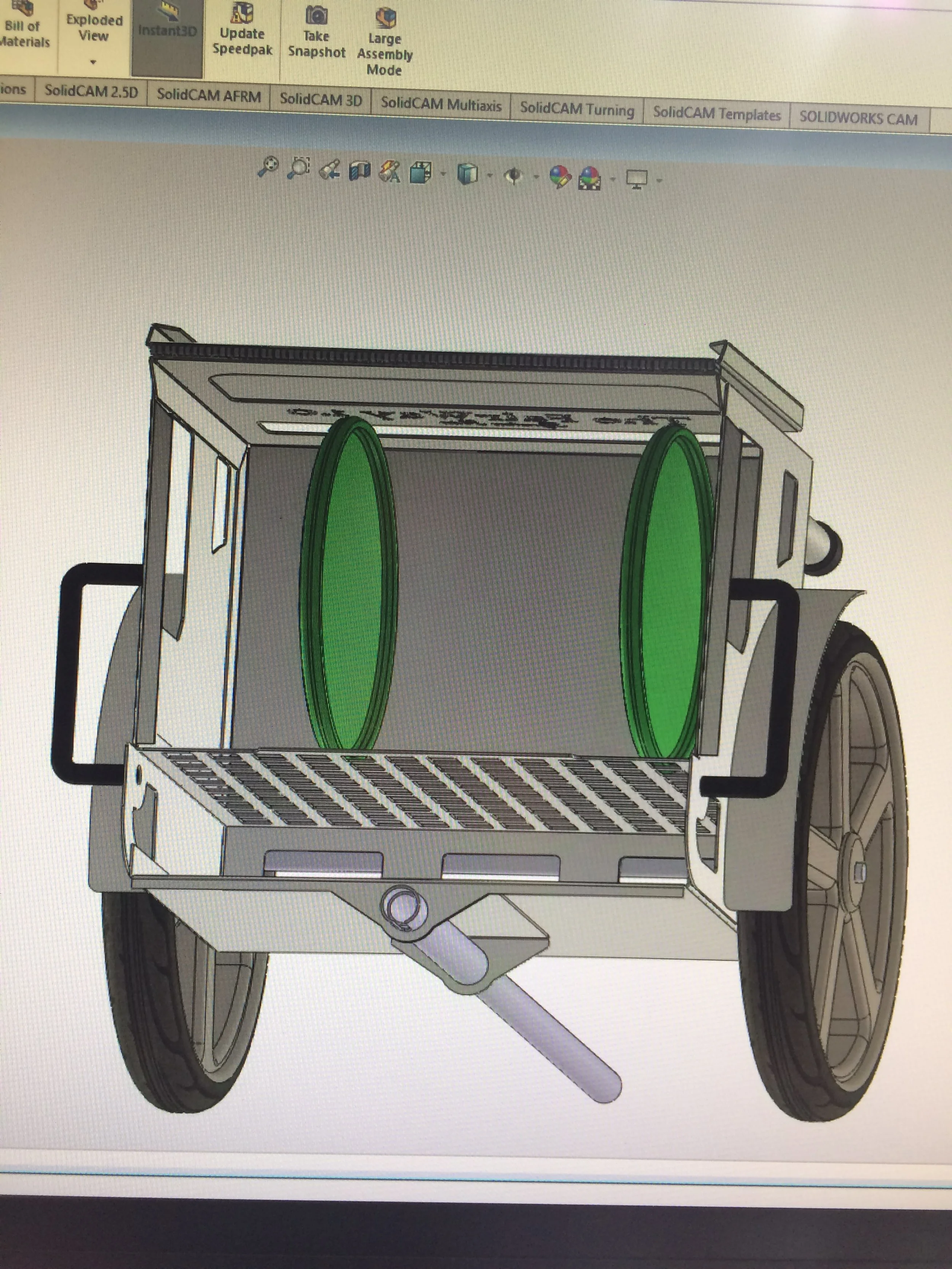

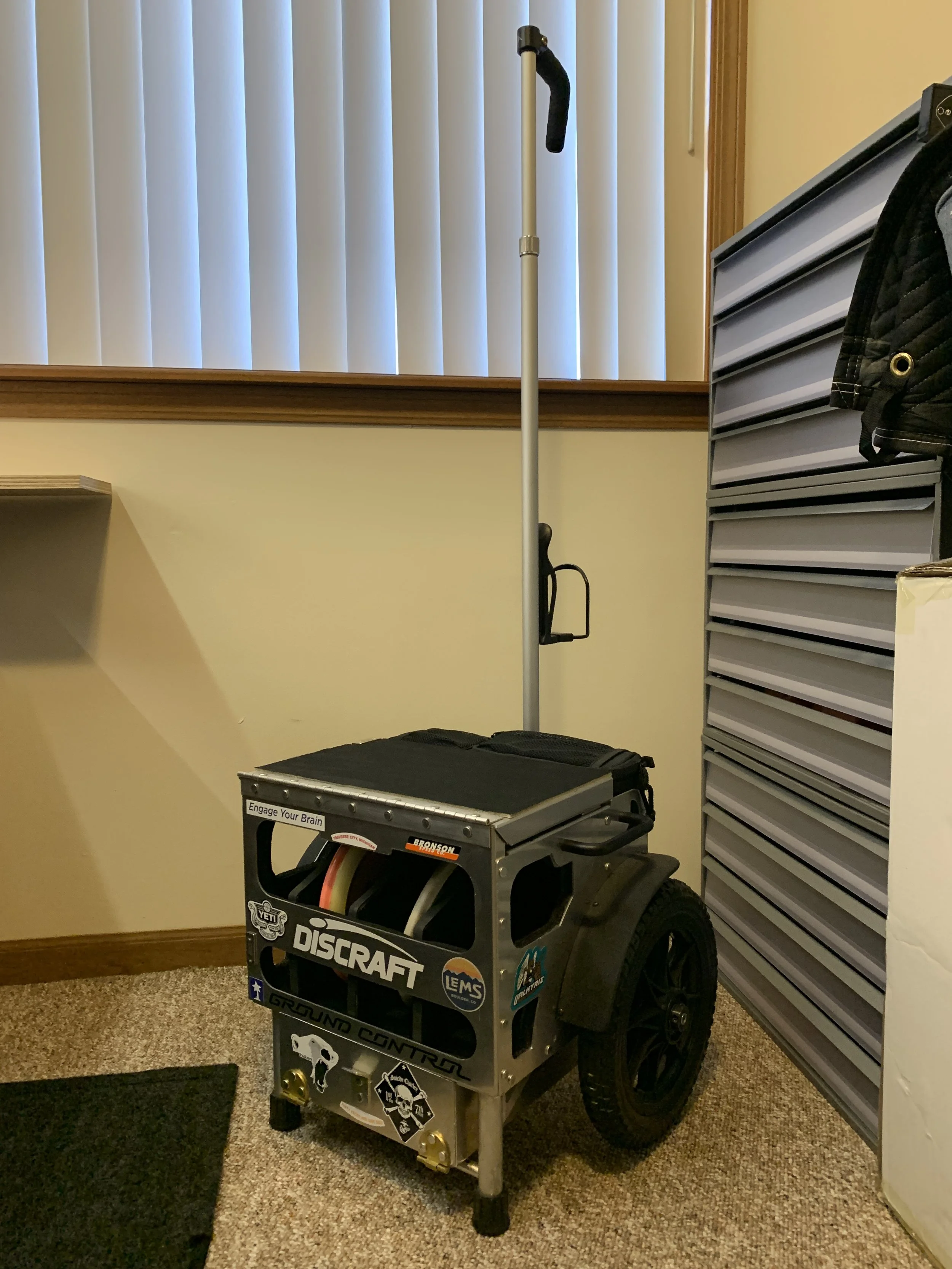

I wanted to design a portable disc golf cart using SolidWorks' sheet metal features. For me it needed to be big enough to carry a minimum of 15 discs with storage enough for water, snacks, bug-spray, and a rain coat. I also wanted the cart to double a seat, so the cart design needed to be strong, stable, and robust.

-

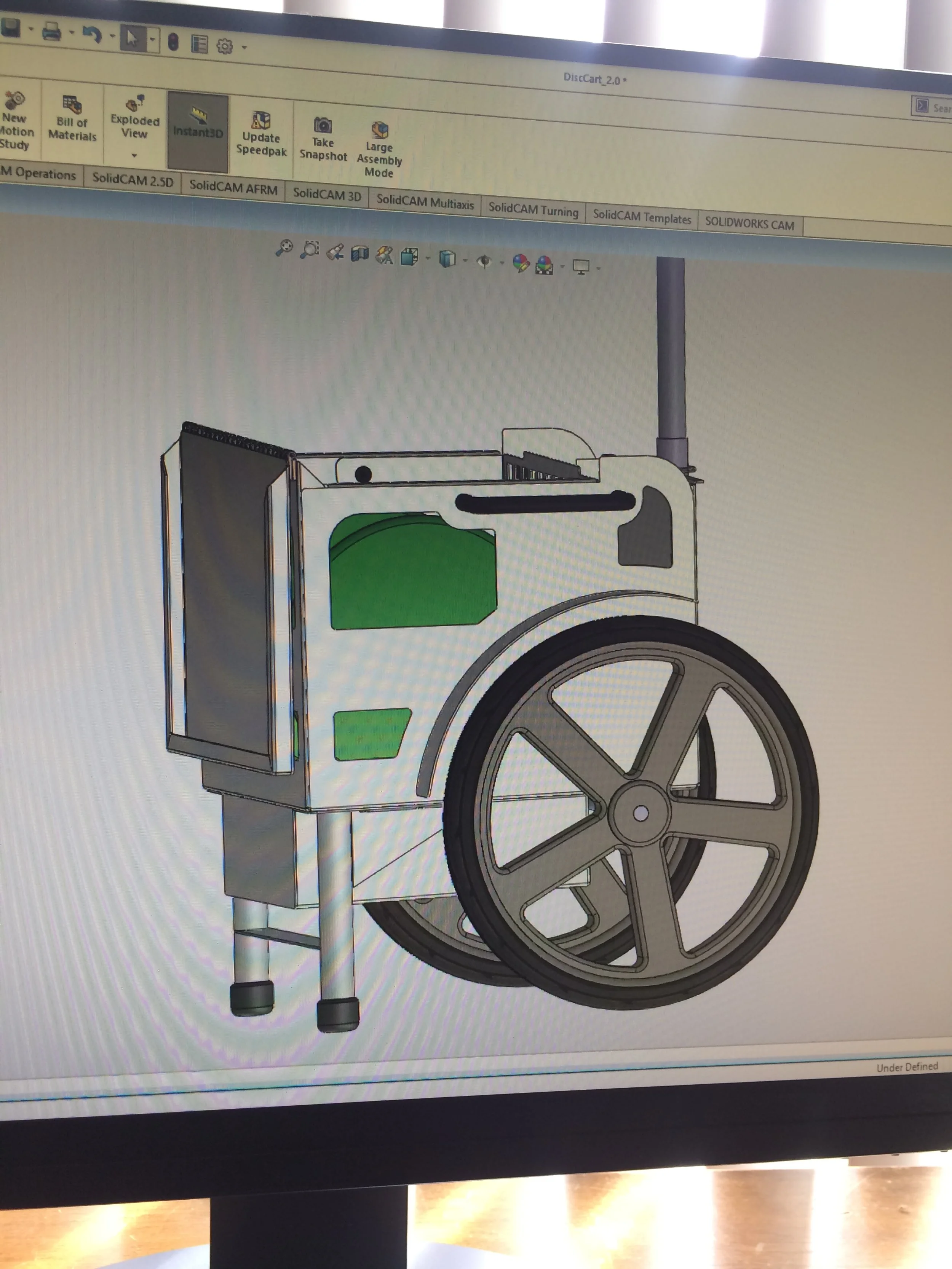

Designed in SolidWorks

Laser cut and press brake formed

Rivet construction

275lb Max weight

Magnetic lid retention

Open rear storage with bag and cooler

Under chassis storage

Additional storage on underside of lid

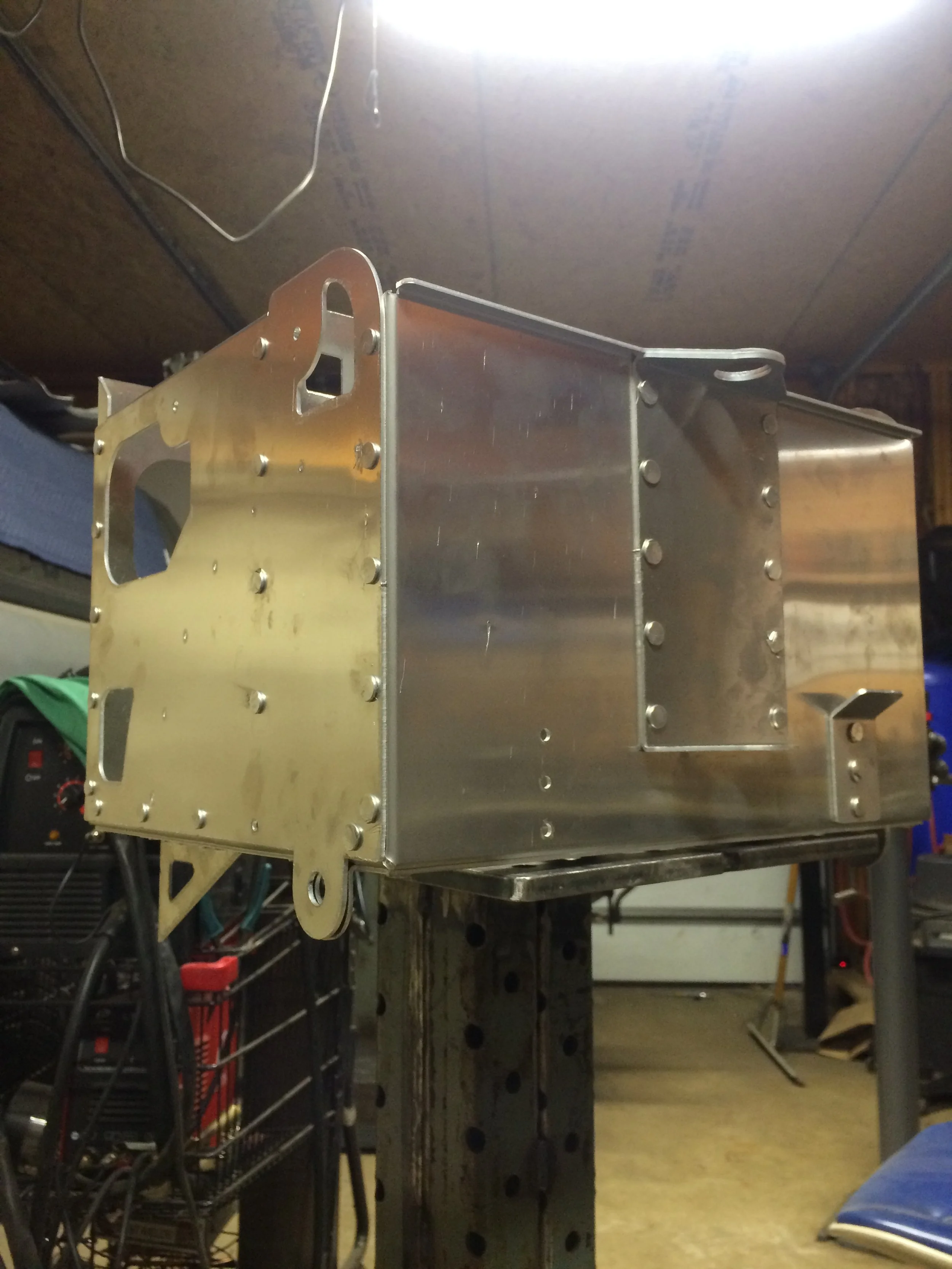

14-gauge 6061 aluminum

Piano hinged main lid

Side carry handles

12” Tubeless wheels

Rigid mudflaps

Telescoping and detachable handle

3 Padded internal dividers

-

Lessons:

Each machine shop has their own tooling and tolerances. Because of this, communication durring the design phase is a must. This allows you to set correct tolerances and also ensure your CAD design can be produced with the tooling they offer.

Outcome:

The cart has made countless trips to the disc golf course over the past few years and I really enjoy using it. The design didn't require any revisions and assembly went smooth. The rivet construction has been very strong and was worth the extra effort in the assembly phase.

Overview

A robust storage solution for discs and gear out on the course which doubles as a seat during course backups.

↓↓ Photos ↓↓

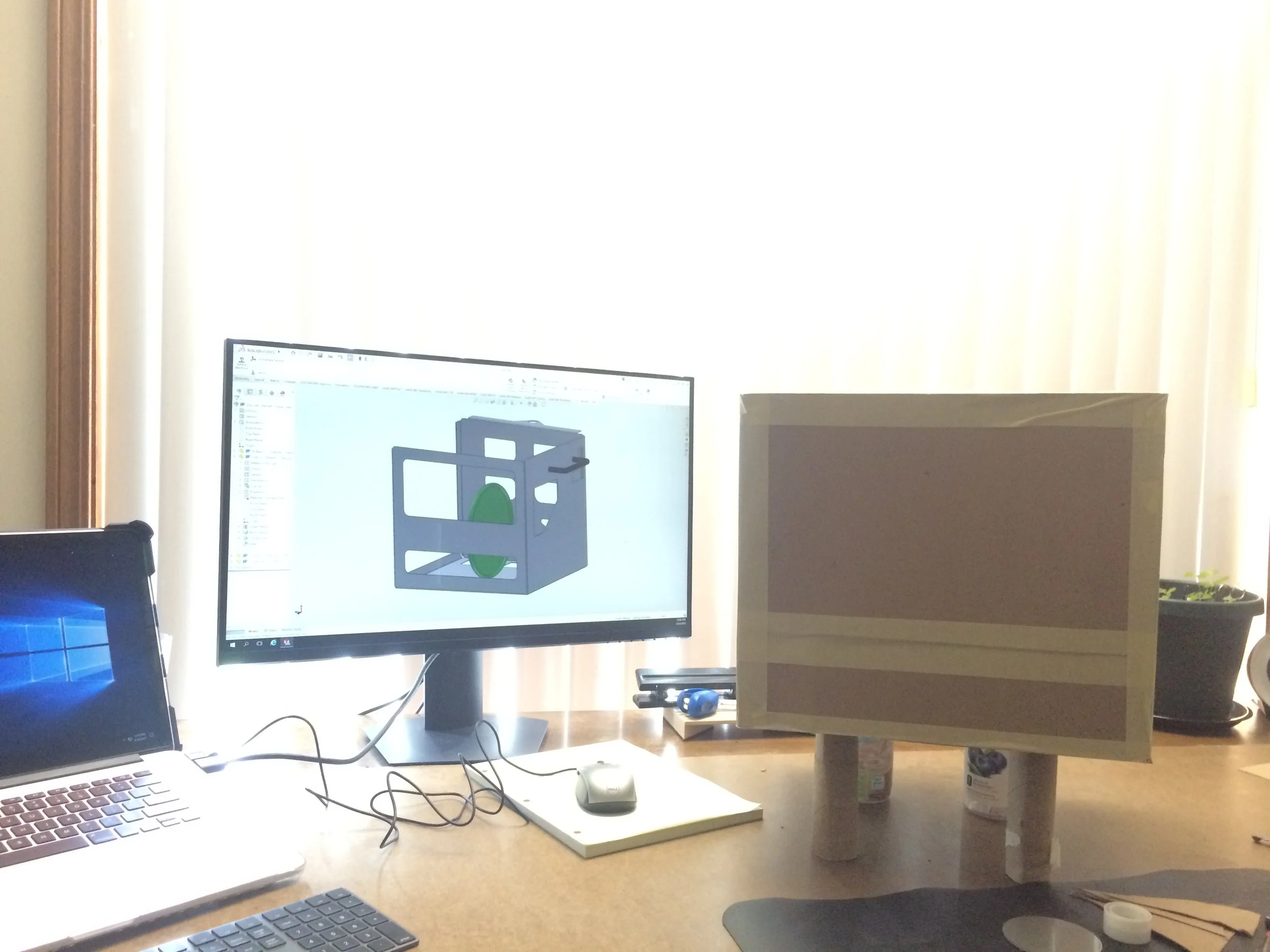

Prototype

A cardboard prototype was made to ensure the cart could fit in an average size trunk. These overall dimensions were transferred to the CAD model.

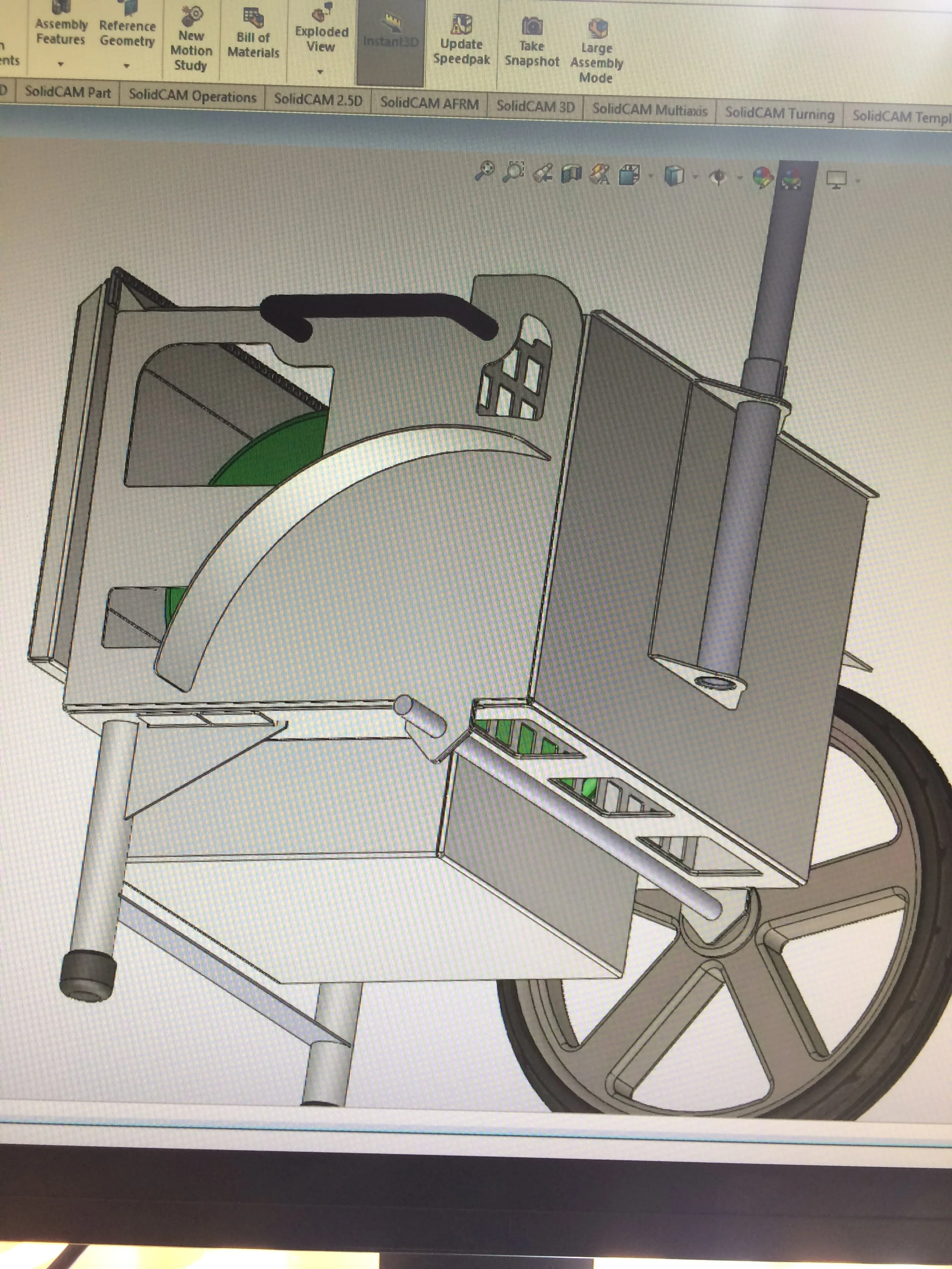

Mechanical Design

This design was based on an existing product made by a company that’s no longer in business (Delta Disc Cart). I used many images of the cart to model mine after, along with some custom features that I thought were improvements over the original design.

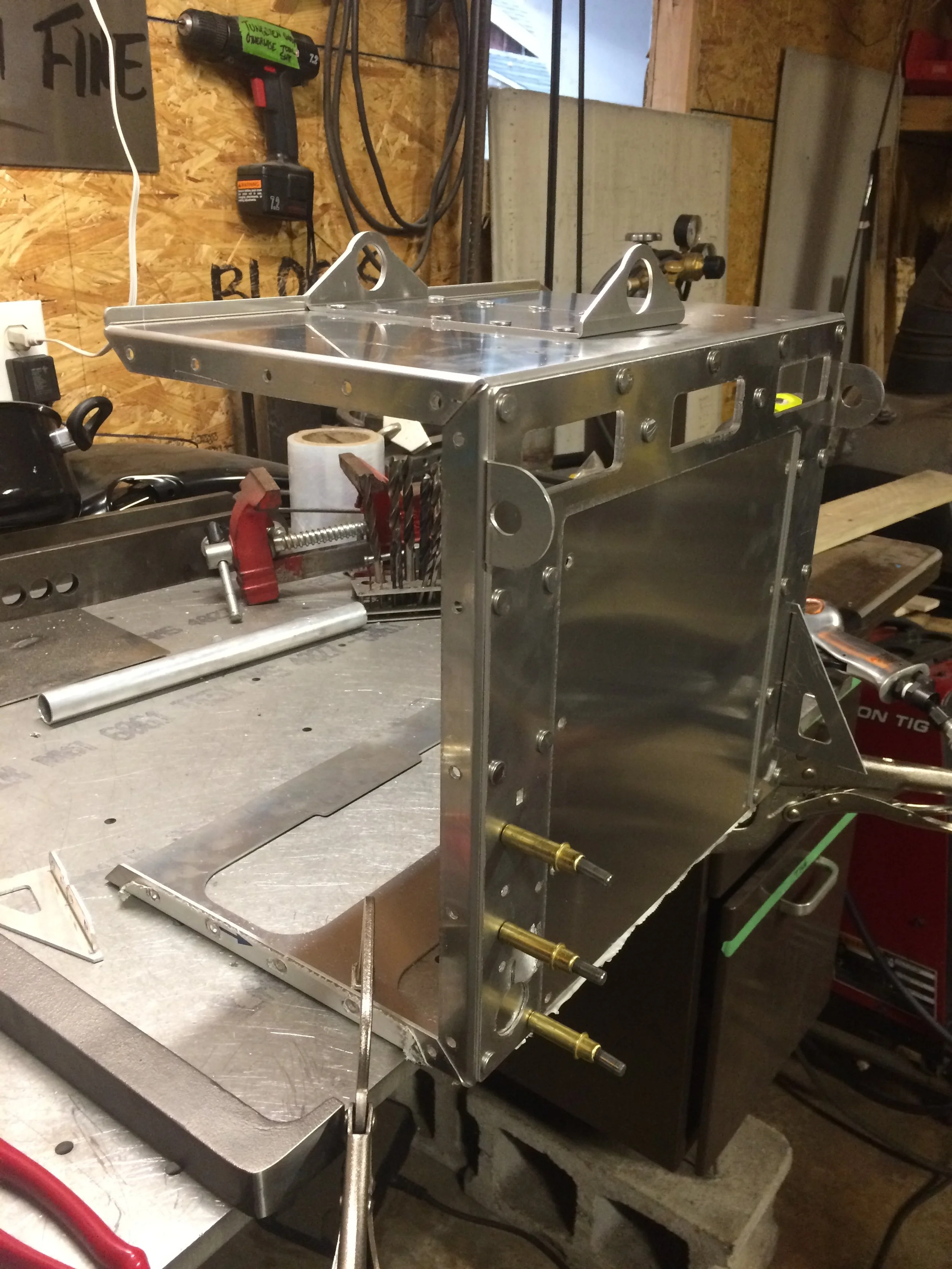

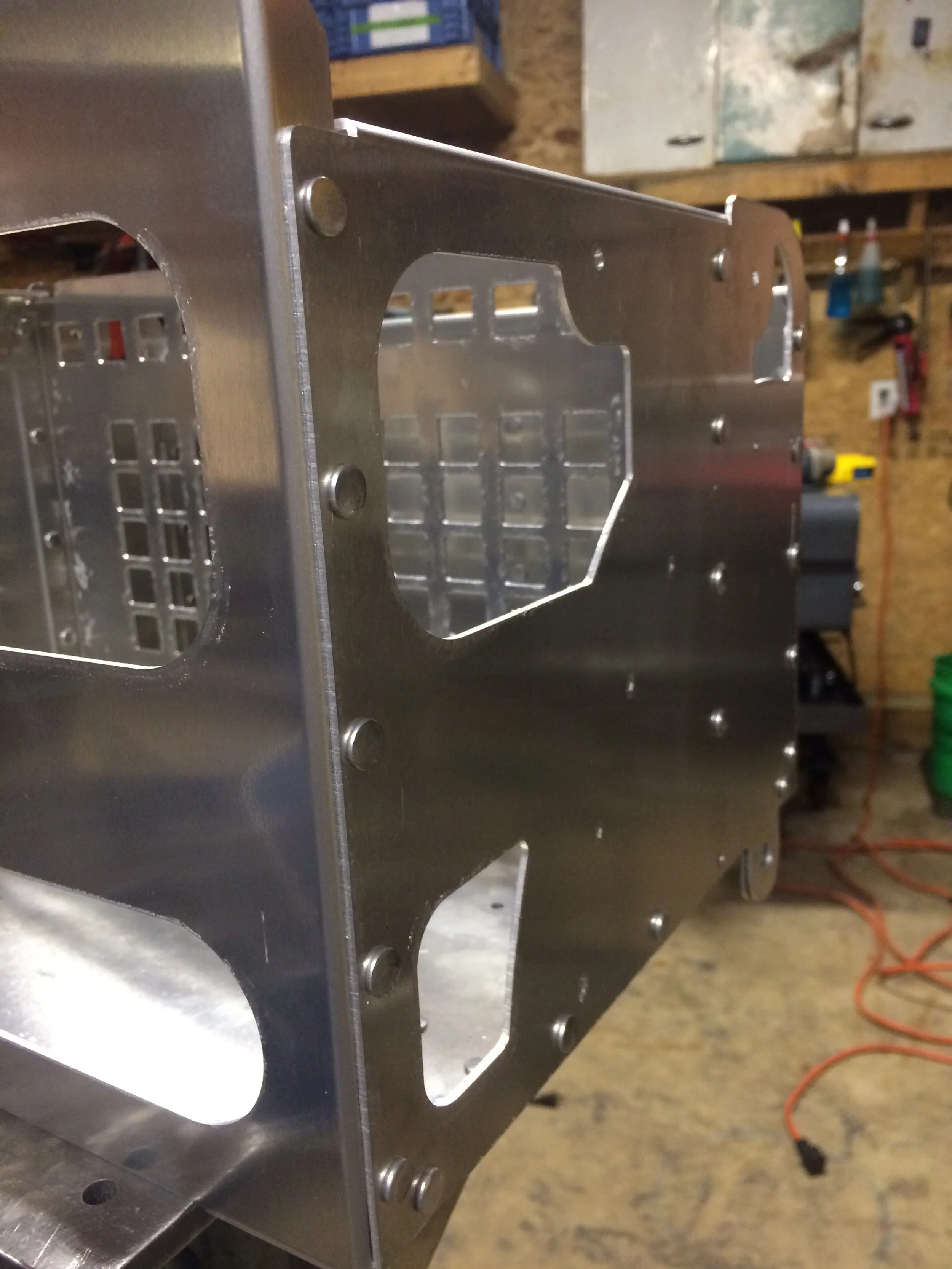

Production / Assembly

The CAD files were exported as .dxf files and arranged in nesting software for the laser cutting process. Drawings were used to determine bend line dimensions in the forming process using a CNC hydraulic press brake. Clecos were used to hold the panels together during the assembly process.

End Result

With 3+ seasons of use, the cart continues to be extremely reliable, comfortable to use, and remains just as robust as the day it was built.