Engine Rebuild

Nov 2023 - Mar 2024

-

Determine and repair the cause of its excessive oil consumption, misfires, and leaks.

-

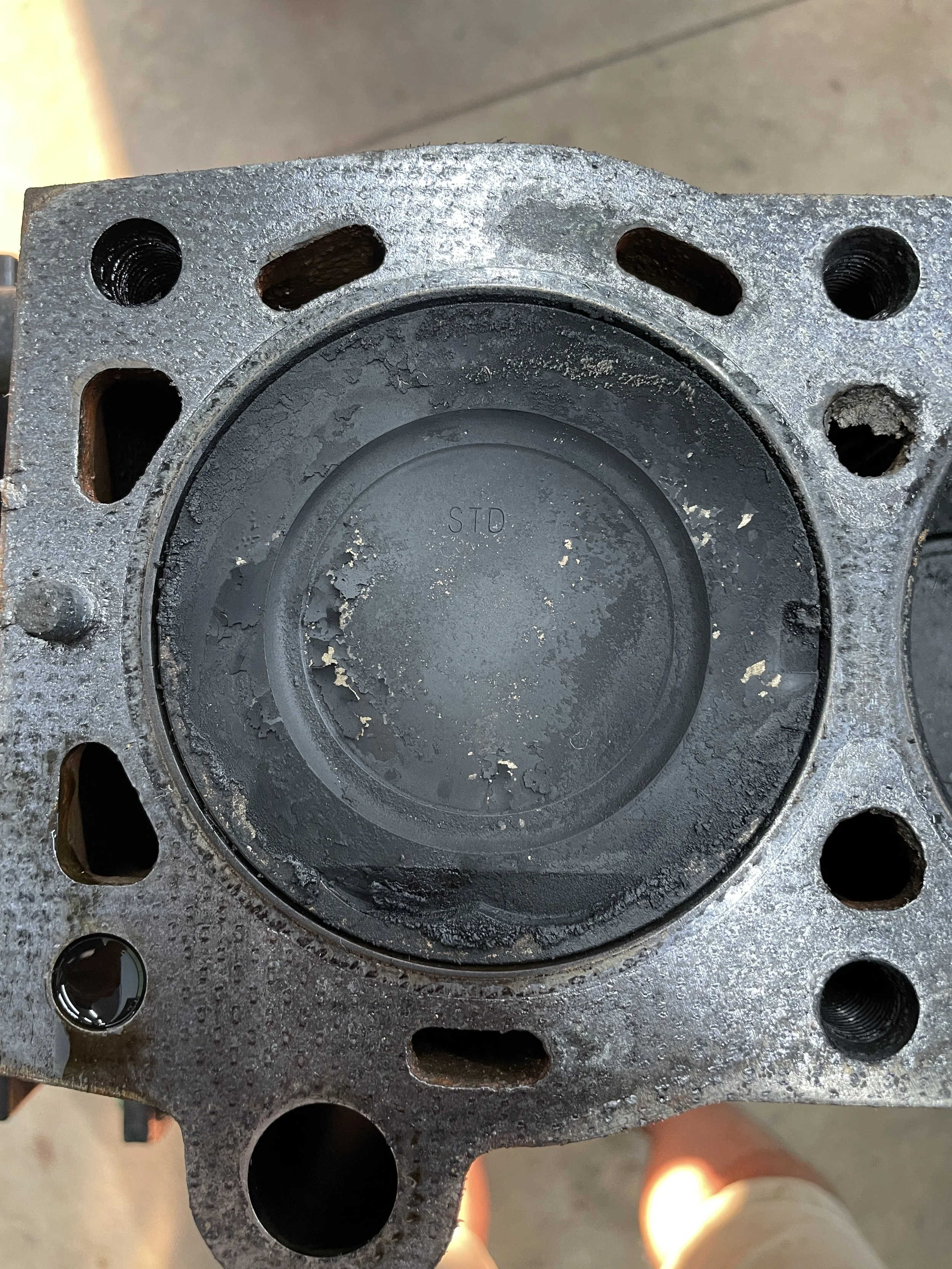

Block & crank insp. and machined by local engine builder

Bored 0.020” over

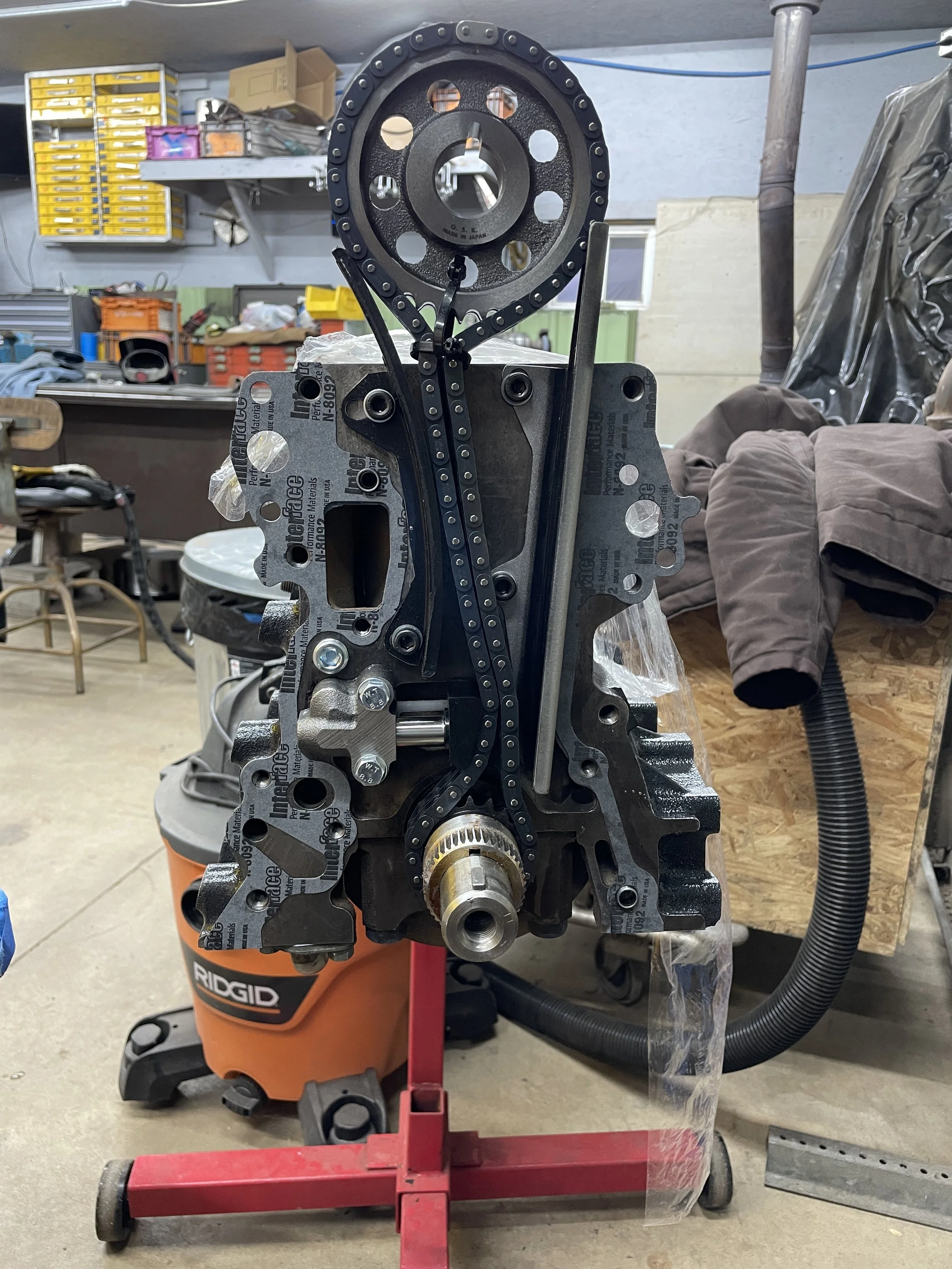

Dual row timing chain upgrade

Ported performance head with oversized valves

Upgraded cam with lobe profile to optimize air flow

Restored engine wiring harness

Oversized piston/rings

Water pump / oil pump

Clutch, pressure disc, and flywheel

OEM Replacement components where possible

-

Lessons:

The best method of rebuilding an older engine may not come from the repair manual written by the manufacturer. Over time, design weaknesses get observed and documented, therefore it's important to cross reference information from forums and experienced engine builders to find the best practices.

Outcome:

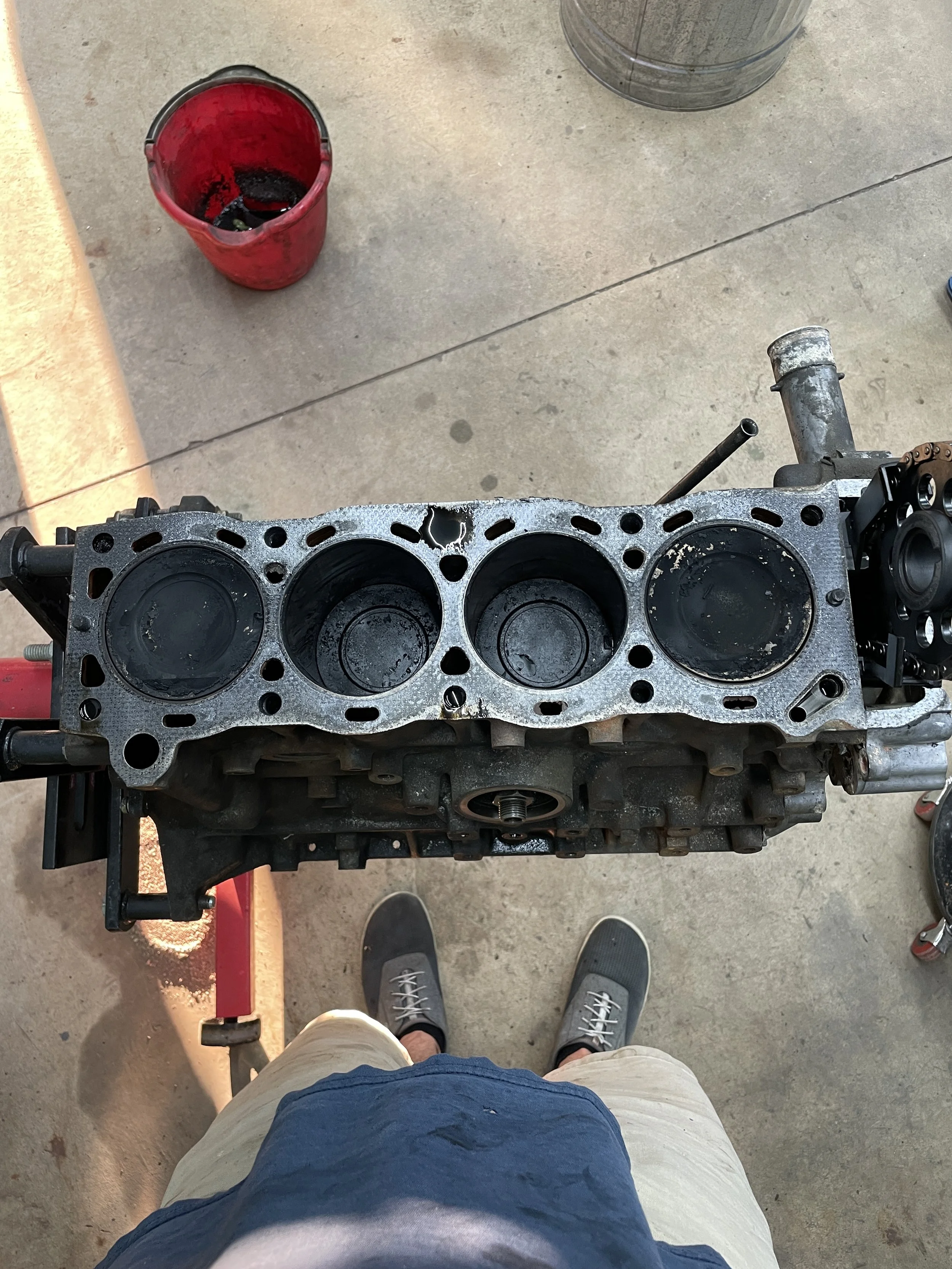

During the mechanical inspection of the block it was found that the cylinder walls were slightly egg shaped allowing oil to seep past the piston rings, causing the excessive oil consumption. This required machining to resolve and was done at a local engine machine shop.

This was a poorly maintained engine and needed a lot of replacement parts to get it back to good health. The engine is now fully rebuilt and waiting to be installed in the truck.

Overview

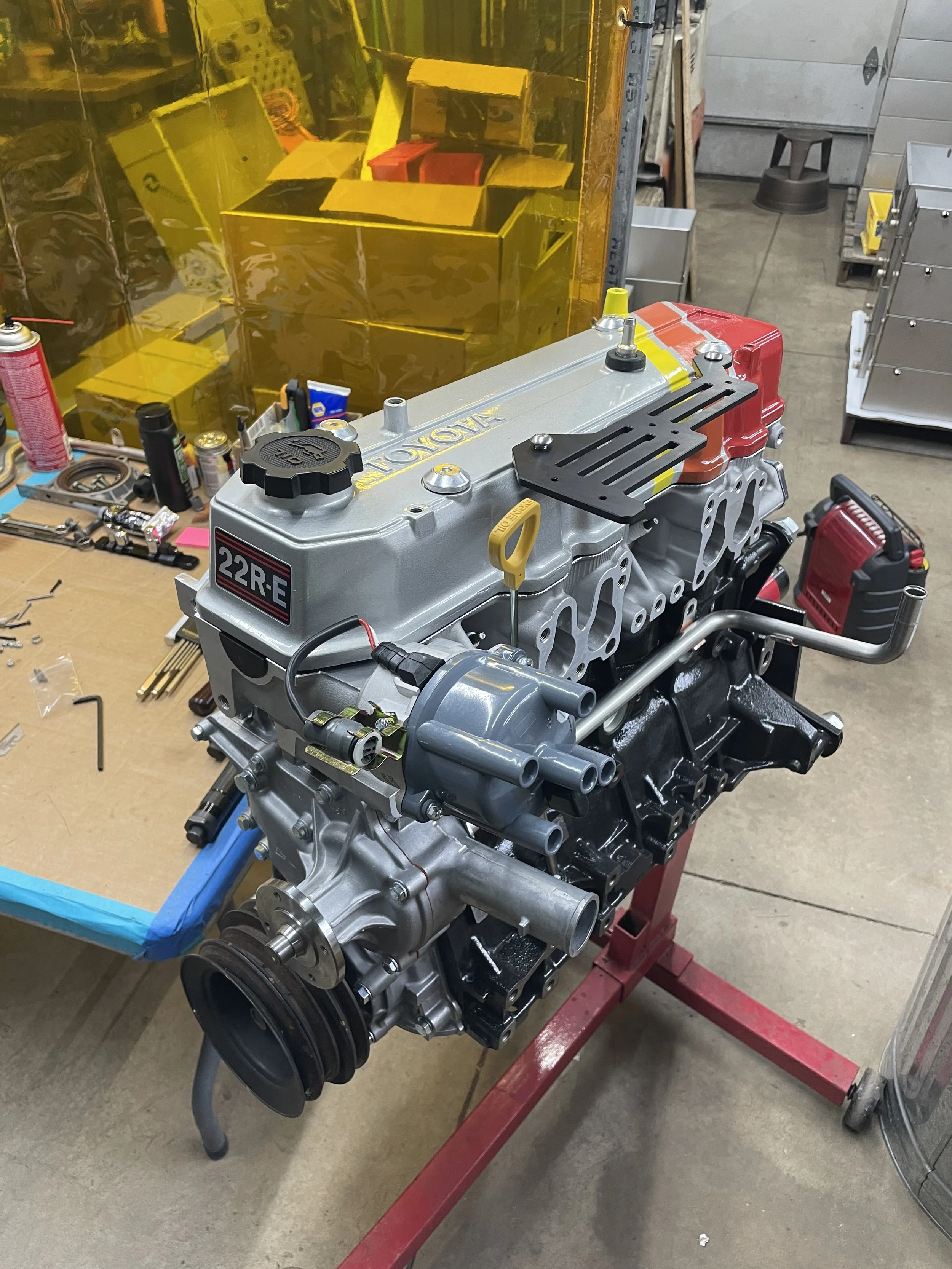

A complete engine rebuild with sensible performance upgrades.

↓↓ Photos ↓↓

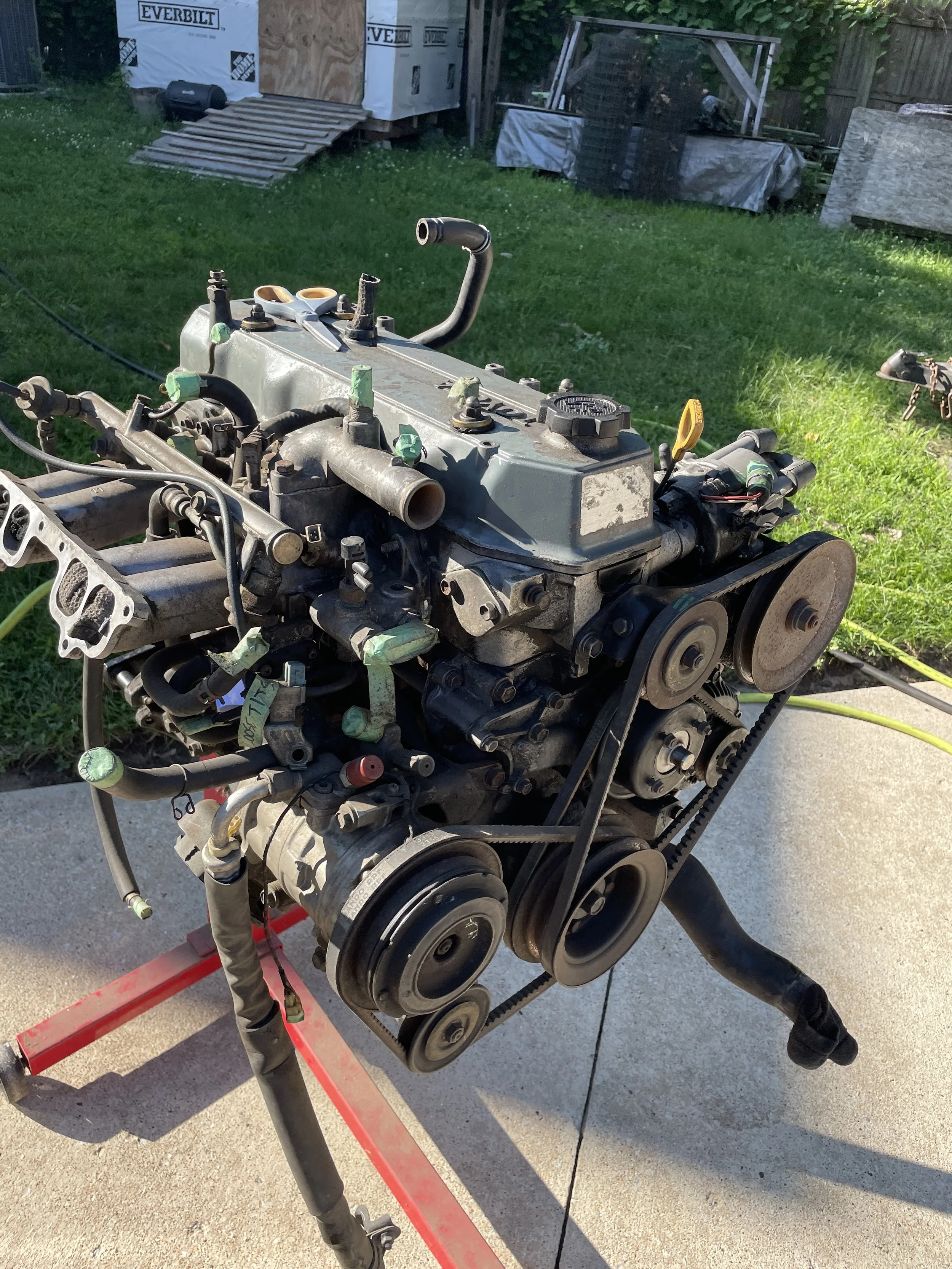

Before Rebuild

The vehicle spent most of its life in the California desert, which dried out most of the seals. Because of this, it leaked just about every fluid it had. It also suffered from overheating and excessive oil consumption.

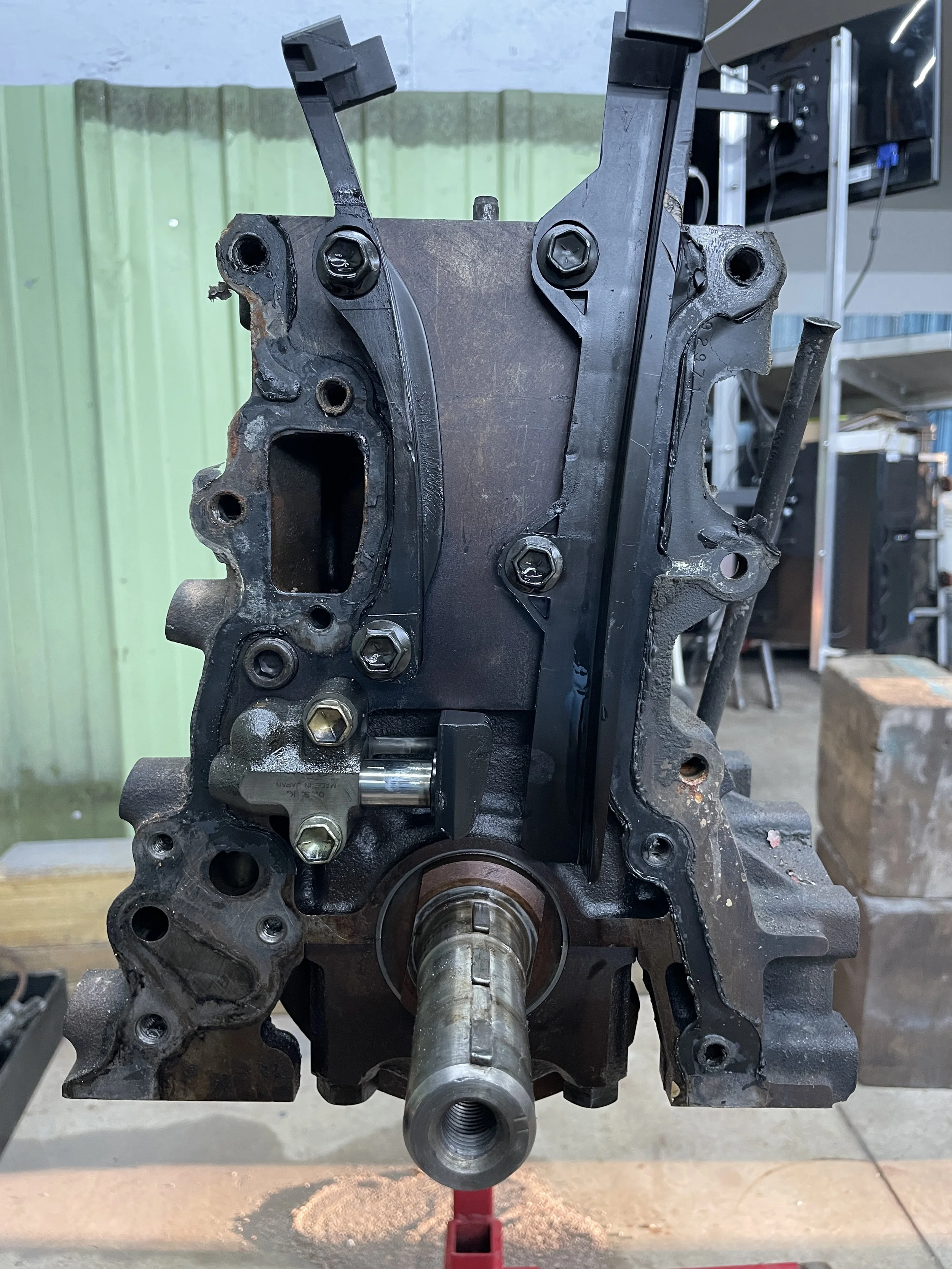

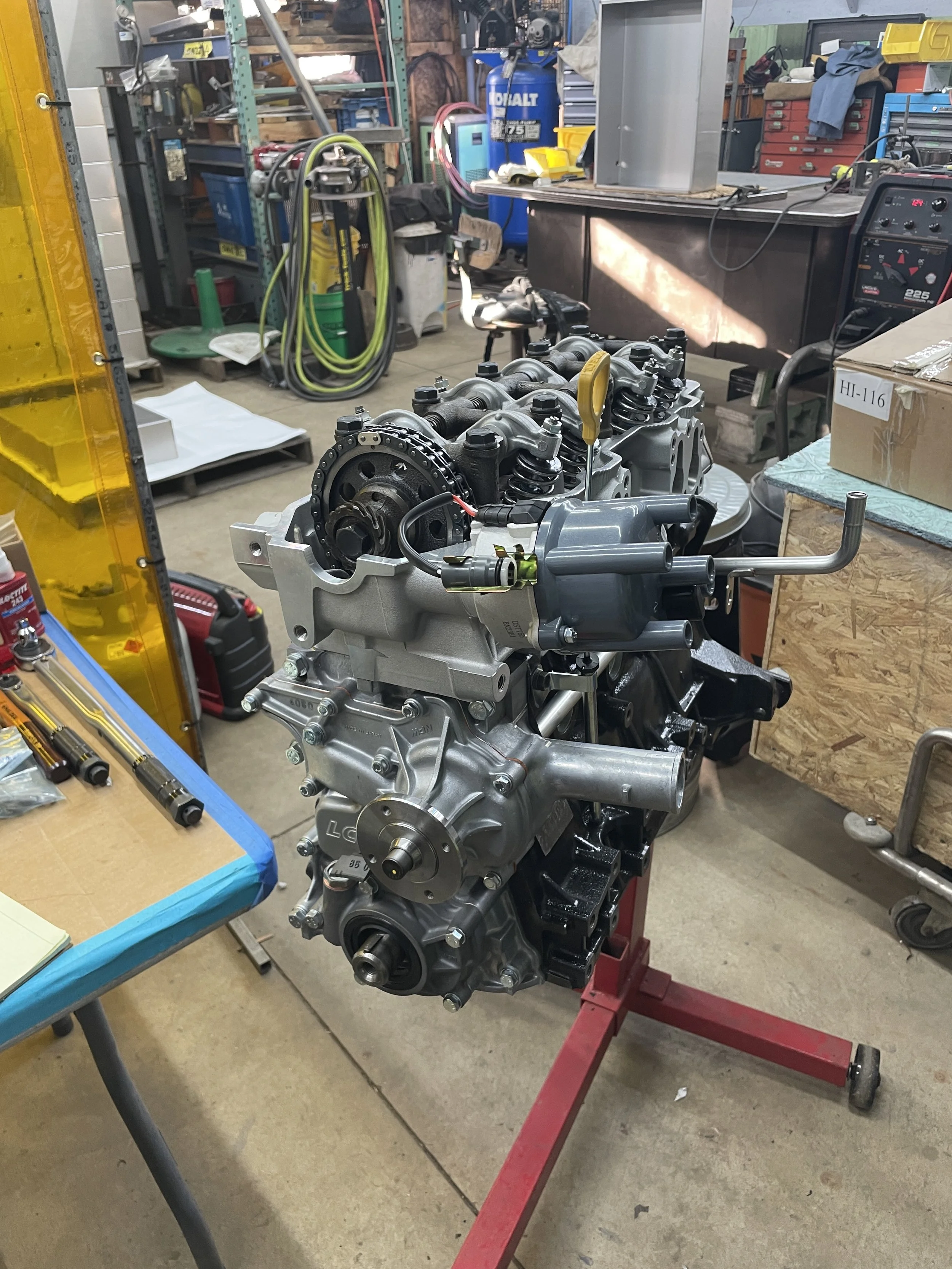

Rebuild

The engine was stripped down to the block and sent to a machine shop for inspection and machining. Once machining was finished, reassembly began. Sourcing parts was a challenge, but I created a spread sheet to make the process easier.

After Rebuild

This engine had 262,788 miles on it before the rebuild and, since it’s essentially a new engine, should go another 250,000 miles before needing another.