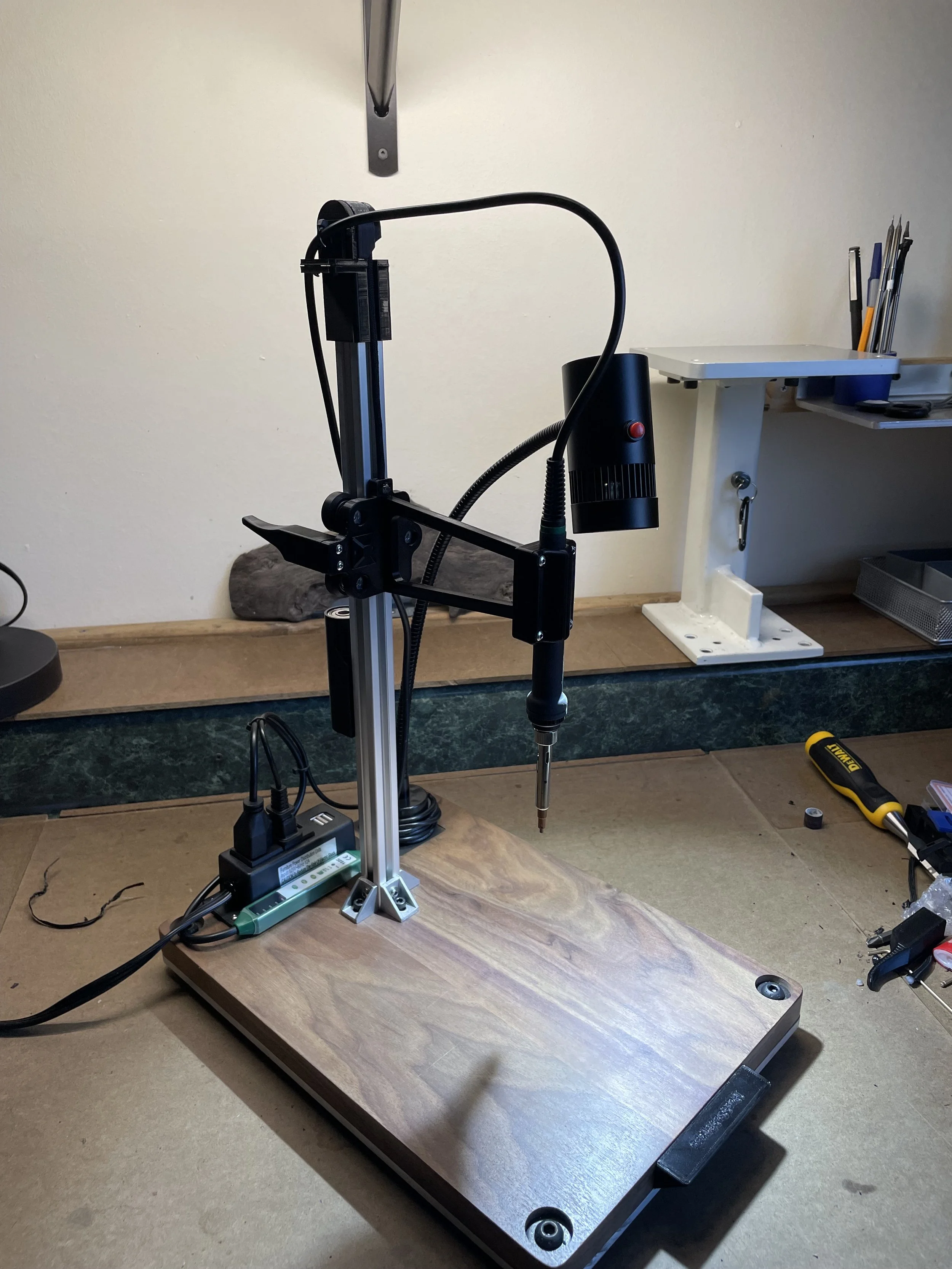

Threaded Insert Press

May 2022

-

Modify an existing design to produce a tool which can reliably install threaded inserts into thermo plastics.

-

Designed in SolidWorks

3D printed with PLA

Aluminum-backed Oak butchers block

Rubberized work surface

16” Extruded aluminum vertical track

Counter-weighted press arm

Adjustable heat settings

-

Lessons:

Rigidity is your friend in pressing type designs.

Outcome:

This press has installed over 1000 threaded inserts and has worked extremely well. Without a tool like this, it is very easy to install the inserts crooked, making it very difficult to get screws to thread.

Overview

A manual press for the repeatable installation of threaded inserts into thermo plastic substrates such nylon, pla, abs, and polycarbonate.

↓↓ Photos ↓↓

Design / Build

A 3/4” piece of Walnut backed by 1/4” sheet of aluminum provided a flat and sturdy base for the press. The work surface was illuminated by an attached light and covered with a rubber mat to provide a slip free surface. The prototype boom was redesigned to increase rigidity after testing.

End Result

The end result looks as good as it functions. With over 1000 threaded inserts installed to-date, the press has been extremely reliable, comfortable to use, and is quick to setup and operate.